ALL ABOUT STERILIZATION POUCHES

Sterilization Pouches

A sterilization pouch is a single use package which holds items inside during sterilization process. It is used in a sterilizer to allow penetration of the sterilant to the items placed inside. Sterilization pouches conserve the sterility of the item after the sterilization. Sterilization pouches diversifies according to the item’s dimension, weight and the sterilization process applied.

What are the components of a sterilization pouch?

A sterilization pouch is made of two main components such as paper and plastic film adhered together by heat seal or with an adhesive tape. Medical grade paper or Tyvek® is used in paper part of sterilization bags.

The plastic side is made from a transparent polypropylene/polyester laminate film for medical grade paper and polyethylene/polyester laminate film for Tyvek®. The plastic side of the pouch enables clear visualization of the item inside and the chemical indicator on edges of the pouch.

The paper side is designed to allow penetration of the sterilant and air removal. Medical grade paper is used for steam, EO (Ethylene Oxide) or FO (Formaldehyde) gas sterilization. Tyvek® is used for EO and Hydrogen Peroxide (H2O2) sterilization which is also called plasma sterilization. Besides Tyvek® is also used for alternative sterilization methods such as Ozone, Gamma sterilization etc.

Chemical indicators on edges of sterilization pouches are Type 1 indicators that measure whether the sterilization parameter which can be steam or chemical gas exposure is satisfied. If the sterilization parameter is satisfied, then the chemical indicator changes colour.

How to select a proper sterilization pouch?

Sterilization pouches are recommended to pack lightweight items. The pouch should be of the right size to enclose the item packaged and offer right type of built-in chemical indicator. The pouch must allow penetration of the sterilant which can be chemical gas, heat, steam or vapor. A proper pouch size is important. The item mustn’t force the seams and risk punctures on the pouch.

Sterilization reels or sterilization rolls are preferred by users for various sizes of items. Because sterilization reels can be cut into the desired length. So the pouch cut from a sterilization reel will have both ends open. The user will heat seal one end, then place the item into the pouch and then heat seal the other end.

Medical grade Kraft paper used in sterilization pouches should have a basic weight of 60-70 gsm. The medical paper is porous in order to enable the sterilant to enter and exit the pouch through the paper side and must ensure that the pores close during the drying process to maintain the sterility of items in the pouch.

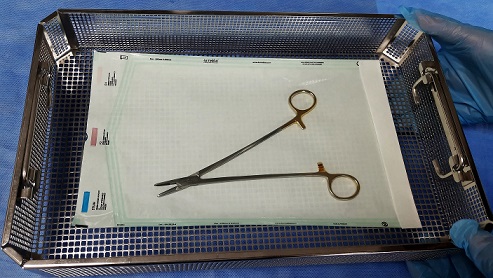

How to pack items in a sterilization pouch?

Items should be placed at least 2 cm of clearence from all sides of the pouch. Items should fill at most 70% of total volume capacity of the pouch. Hinged instruments should be placed in a open position. Curved intruments should be placed such that the curved part will be toward plastic side of the pouch in order to prevent punctures through the paper side. It is recommended to use instrument protectors for the items with sharpe tips to avoid punctures through the pouch.

Sterilization pouches are either self sealing or manually heat sealed in order to close. Excess air in the pouch should be removed before sealing.

How to load pouches into a sterilizer?

Pouches can be placed flat on a shelf or on their edges on a rack, facing the same direction alternating paper to plastic in order to allow circulation and penetration of the sterilant.

After the steam sterilization, autoclave bags shouldn’t be touched until they are completely dry in order to prevent tearing.

What is the shelf life of processed pouches?

Processed sterilization pouches should be stored in room temperature (240) or less and with humidity less than 70%. The shelf life of a processed sterilization pouch is event related which means that the item will remain sterile unless the pouch doesn’t become wet, torn, soiled or damaged. Keep in mind that manufacturer also provide a shelf life and expiration date for sterilization pouches. 4A Medical sterilization pouches conserve the item sterile for 6 months after the process.

Are sterilization pouches reusable?

Sterilization pouches are single use disposable products and shouldn’t be reused. Damaged pouches shouldn’t be used for sterilization.

Why choose 4A Medical sterilization pouches?

4A Medical provides various types of sterilization packaging solutions consist of sterilization reels, gusset reels, Tyvek® reels, reinforced reels and sterilization pouches, self sealing pouches, gusset pouches, Tyvek® pouches and reinforced pouches. You can find the needed pouch according to the required dimension.

4A Medical offers more than 20 years of experience and know-how. 4A sterilization pouches are manufactured in our own facilities with the cutting edge technology. Our quality department checks the quality of the products in all stages. We test each batch before the delivery.

4A sterilization reels and pouches have three indicators on edges for steam, EO and FO sterilization processes.

4A Medical offers gusset reels and pouches for larger items since they have a higher internal volume.

4A Medical produce sterilization reinforced reels and pouches besides Tyvek® reels and pouches for heavier items since they have more resistance against tearing.

Sterilization is a critical process for infection control whose importance is reminded by the Covid-19. The pandemic demonstrated how vital hygiene, disinfection and sterilization are. Thus top quality is required in all aspects including raw material in order to receive the best results. 4A Medical places importance to the quality through starting with the selection of raw material. 4A Medical uses top quality raw material, combines them in production line with the state of art technology, hence provides the final prodcut in the best quality.

The Sterile Barrier Association (SBA) is the European trade association for companies who produce Sterile Barrier Systems (SBS) and associated equipment and accessories for the healthcare industry. 4A Medical is a member of SBA and contributes to the developments in the association.

The Sterile Barrier Association (SBA) is the European trade association for companies who produce Sterile Barrier Systems (SBS) and associated equipment and accessories for the healthcare industry. 4A Medical is a member of SBA and contributes to the developments in the association.